On July 3, 2016, the last reflecting surface unit of the Five-hundred-meter Aperture Spherical radio Telescope (FA

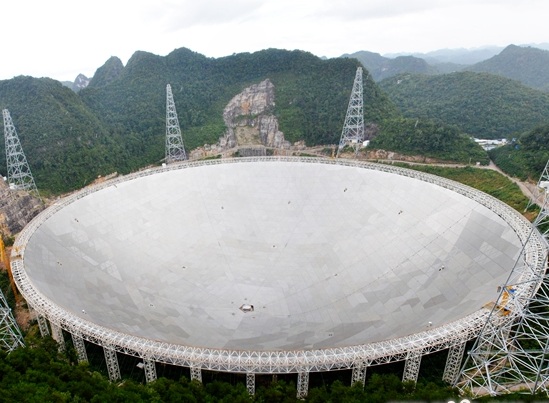

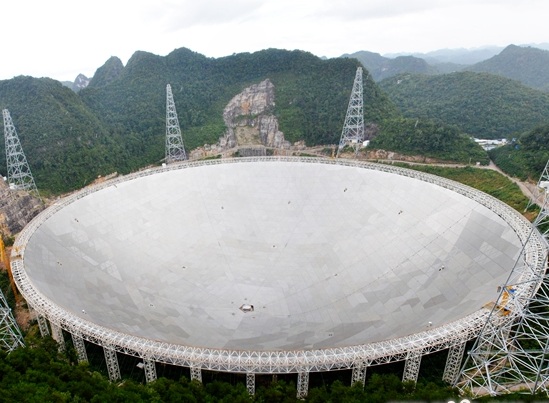

On July 3, 2016, the last reflecting surface unit of the Five-hundred-meter Aperture Spherical radio Telescope (FAST for short) located in Pingtang County of Guizhou Province, was installed by means of crane hoisting. FAST is currently the biggest radio telescope in the world. At the same time, its ability for receiving radio waves from the universe will be of the best. Via a set of data, let’s first see how powerful FAST will be as the champion of the world:

- Aperture: 500 meters, around which 40 minutes are needed for a person to walk for a circle;

- Steel consumption of the outer ring: more than 5000 tons, which is enough for building another Eiffel Tower;

- Steel cables at the bottom: more than 9000, each of which can support 500 adult men;

- Total reflection area: 250 thousands squire meters, amount to 30 standard football fields.

Picture 1: The overall appearance of FAST

The giant skywatch eye brings not only visual impact and shock, but also the highest sensitivity in the world. If you compare FAST to an eye, the feed cabin acts as the pupilla of this huge skywatch eye, which plays the role for focusing. The higher sensitivity and the more accurate positioning of the feed cabin, the stronger capability for it to detect weak radio signal from the universe will be. This is the most important criteria parameter of radio telescopes.

The feed cabin of FAST weighs up to 30 tons, and is hung in the air via the cables from 6 feeding-source-towers, which can be positioned accurately along up-down and left-right directions. However, since it is hung in the air, the disturbance of wind is the biggest enemy for the positioning and focusing of the telescope.

Picture 2: The feed cabin of FAST

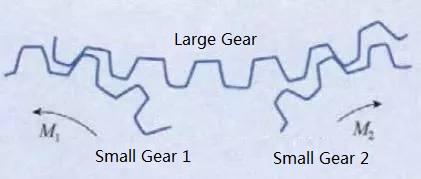

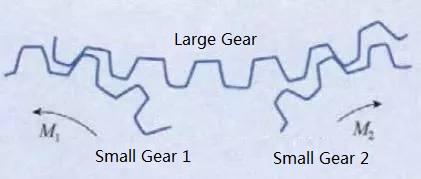

The disturbance of wind is unpredictable, paroxysmal, eddying and inhomogeneous. In order to solve this difficult problem, the feed cabin is equipped with servo control systems, to complete real-time anti-jamming and position compensation. Firstly, the drive control system being composed of 4 servo axes do coarse adjustment to X and Y directions. Secondly, 2 servo axes are equipped for each of these two directions respectively, forming the master-slave relationship, driving two small gears, and then driving a big gear by means of speed coupling via the motion controller and Sercos bus, and so is able to complete anti-backlash. The positioning accuracy is 48 mm.

Picture 3: The drive control system of the feed cabin of FAST

Picture 4: The gears of the feed cabin of FAST

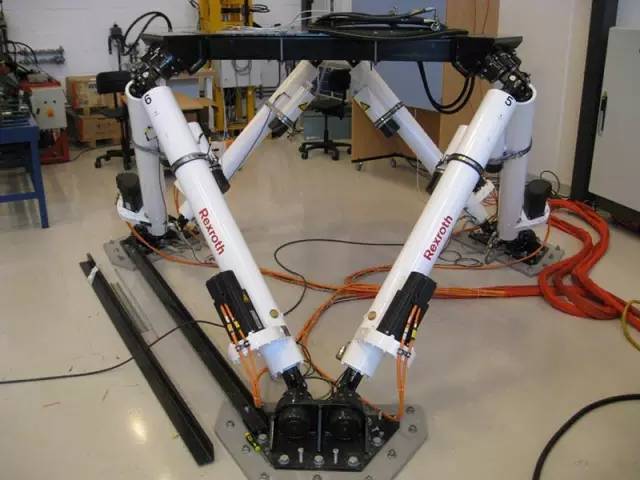

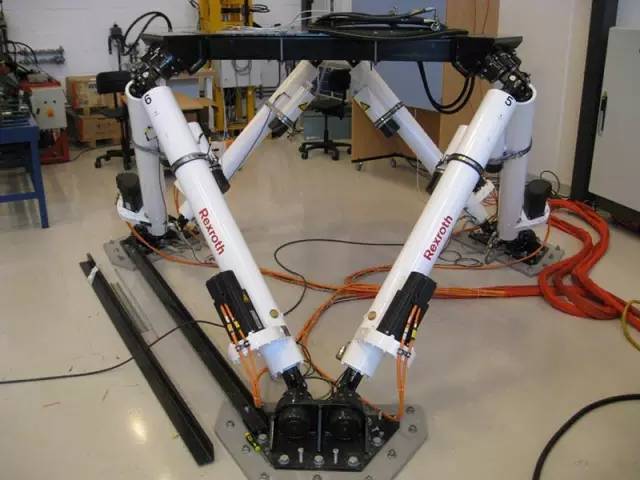

Other 6 servo drive axes drive the electric poles to form the Stewart parallel mechanism, which accomplish computing and compensation for 6 degrees of freedom in real-time with the motion controller, and send the position command via the Sercos bus, to complete the fine tuning for the position compensation of the feed cabin. With a cycle time of 1ms, the cyclic command value input of the drives for position control can be transferred quickly in real time. The positioning accuracy of the feed cabin can be 10 mm or less. Finally, with the 10 servo axes, the position compensation of the feed cabin is achieved in real-time, making the telescope as solid as rocks and mountains during the course of positioning and focusing.

Picture 5: The Stewart parallel mechanism of the feed cabin of FAST

Theoretically, FAST can receive electromagnetic signals 13 billion 700 million light-years away, which is close to the edge of the universe that human beings can observe. It extends the space measurement and control ability of China from the moon to the outer edge of the solar system! It will find things we've never seen before. At the same time, it’s extremely high detection sensitivity is 2.5 times higher than the currently most advanced telescope in the world – the American Arecibo, and will maintain world top-class status in the next 20-30 years.

The successful design and operation of this excellent application system benefit from the excellent Sercos-based control and drive products provided by Bosch Rexroth – the globally leading drive and control expert.